We are an ISO 9001 and IATF 16949 certified company and take adequate measures to achieve total quality in all our operations. Our quality policy has always been that “satisfying customers by delivering precision components, understanding their needs in terms of product quality, delivery schedule and services”. The quality control department is equipped with all necessary testing equipments, used by a technically qualified team. We are Conducting Documented PPAP Activities with quality control at every stage right from receipt of raw materials to delivery of finished goods to make sure our products can measure up to international standards.

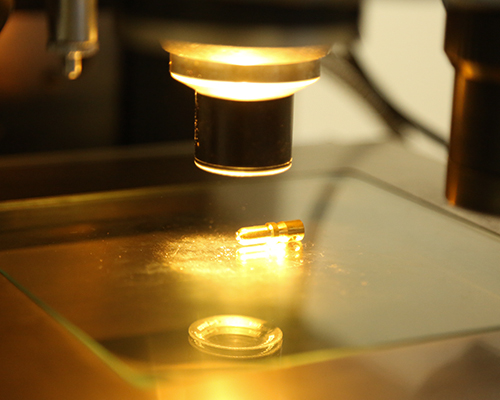

we have profile projector used to measuring. It is used by our quality specialists only to make sure about quality of finished products

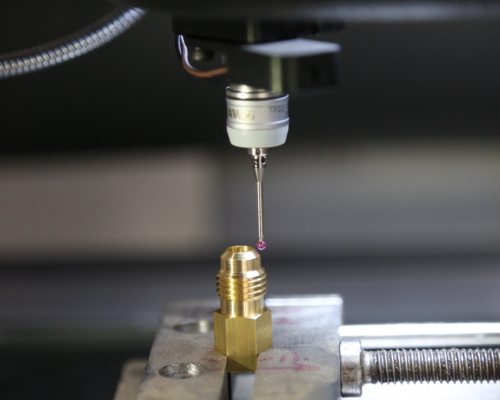

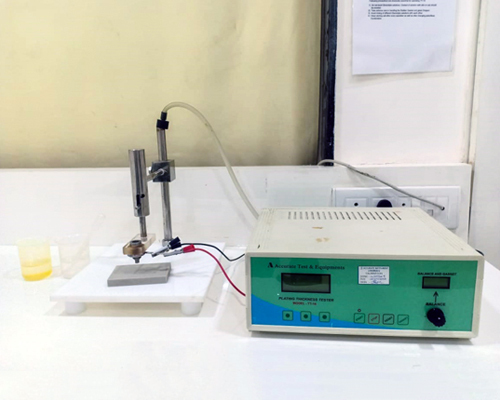

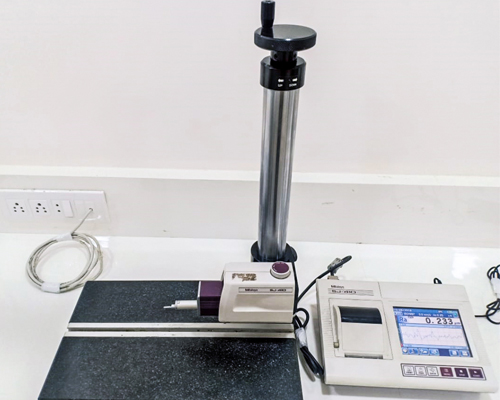

We have shop-floor measuring equipments and master equipments used in our company. Master Equipments are used only by Quality Engineers whereas shop-floor equipments are used by master technicians and technicians. All gauges and measuring equipments are calibrated and we take utmost care of these equipments.

We have To check surface roughness. All products are checked and reports are generated and records are available if required

We offer laboratory services, in accordance with international, national and industry specific standards, or client specifications, for clients in quality assurance.

Trained engineers performs First Pieces approval, In-Process Inspection cross checking and Final Inspection. Readings are measured using our calibrated equipments and recorded. Every component manufactured has a batchwise jobsheet that describes the PPM Level of the product with details of the non-conformance. PPAP Documents upto level 5 can be provided on request.

As a responsible corporate citizen, Alliance Metal India is committed to protecting human, natural resources and the local & global environment by following and executing our environment management system.